Pull-Out Loading Platform

Facilitates the loading and unloading of heavy equipment and machines and enables them to be used outside the vehicle without having to laboriously lift them out.

Product optimizations have made the pull-out loading platform from Sortimo special.

In addition to many practical new functions, it also clearly distinguishes itself through its safety-relevant product properties.

Practically!

Thanks to the new pull-out loading platform for light commercial vehicles or station wagons, the loading space can be used into the furthest corner. The pull-in and pull-out mechanism, which allows the pull-out loading platform to be pulled out of the vehicle by up to 2/3, provides convenient access to the devices, machines and other organization systems stored on it. The payload is permitted up to 250 kg.

Unique!

The infinitely stepless braking function is unique: especially on sloping terrain, the high load on a pull-out loading platform can pose a risk to the operator if it moves towards him without braking. Thanks to the stepless braking function, which takes effect as soon as the operating handle is released, people and nearby objects are protected from the weight of the pull-out loading platform.

System-based and secure!

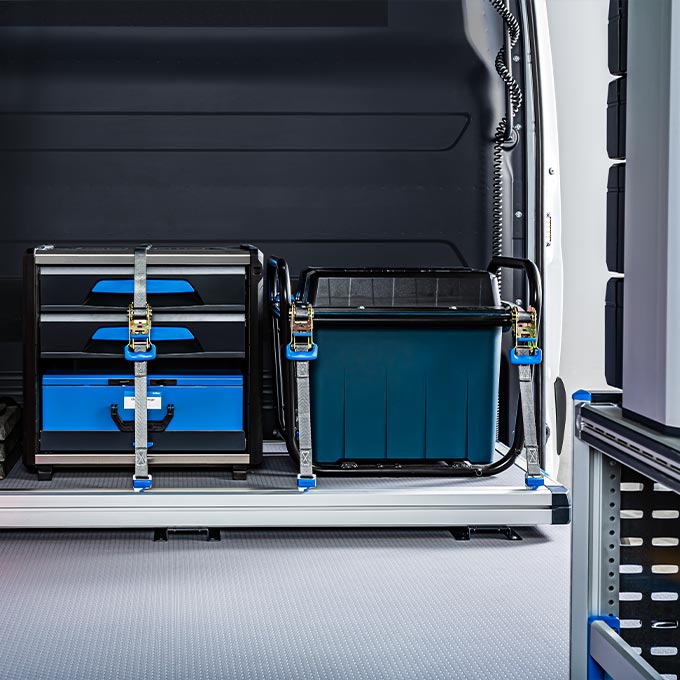

The integrated Sortimo load securing system ProSafe offers another incomparable function, which enables the objects to be lashed on the pull-out loading platform and thus offers a further elementary safety aspect. All Sortimo ProSafe load securing straps can be used as lashing equipment.

All benefits at a glance!

Stepless Braking Function

Especially on sloping terrain, the high load on a pull-out loading platform can be a danger for the operator if it moves towards him without braking. The brake ensures that as soon as the operating handle is released, the pull-out is reliably brought to a standstill in any position.

Payload up to 250 kg

All sizes of the pull-out loading platform are designed for a load of up to 250 kg. This results in a broad field of application. The smooth-running guides ensure comfortable operation even with maximum load.

Integrated load securing

The ProSafe load securing system is integrated in the aluminum profiles of the heavy load pull-out. Existing ProSafe tensioning straps can also be used to secure materials on the heavy-duty pull-out – quickly and safely!

Locking

To ensure absolute safety when driving, the pull-out is locked when it is retracted. The lock engages automatically when it is pushed in and when it is pulled out.

Rounded Edges

Another safety-relevant detail are the rounded edges made of soft elastomer plastic. These prevent the risk of injury caused by commercially available sharp edges.

Resistant surface

The loading area of the pull-out loading platform consists of the tried-and-tested multilayer board, which is also used for the SoboGrip and SoboPro floors, which is characterized by its slip resistance and long-term stability.

2/3 Pull-Out

The loading platform can be pulled out up to 2/3 of its total length. This ensures convenient access to the load, even with a forklift, crane, etc.

Integrated labelling

With mySortimo labels inscription labels and clips, which can also be integrated into the SR5 vehicle equipment, devices, machines and other organization systems can be assigned at a glance on the pull-out loading platform. In addition, information on safety or loading can be made using the labelling clips.

WorkMo Fix

Optionally, on the pull-out loading platform the fixation for WorkMo modules can be integrated so that the WorkMo modules are easy and can be quickly secured on the heavy-duty loading platform.

What our customers say

We asked Sortimo to equip utility vehicles for our field sales team. Our account managers wanted to be able to show GROHE materials to installers during their customer visits. We wanted to do this ergonomically and without harming our employees. To achieve this, we decided to have an SR5 van racking unit and pull-out loading platforms installed in our utility vehicles.

Sortimo was very helpful in understanding how we work. We now have all our materials organised in an orderly fashion and can transport them out of the vehicle ergonomically, safely and with ease!